Metal Profile CD UD UW CW Roll Forming Machine Drywall steel frame construction machine

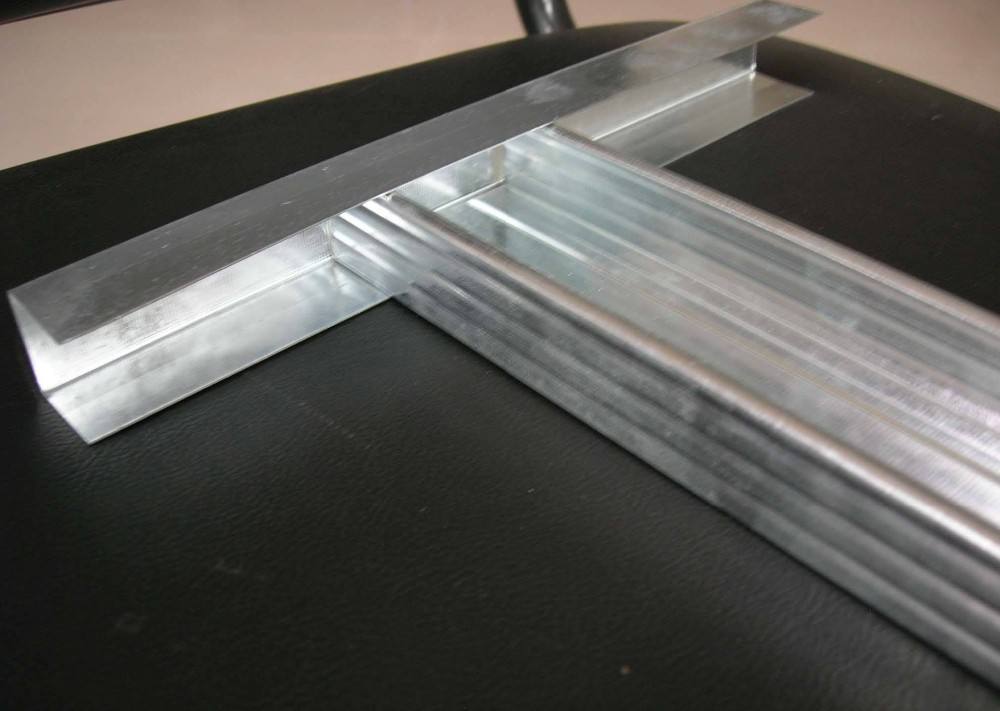

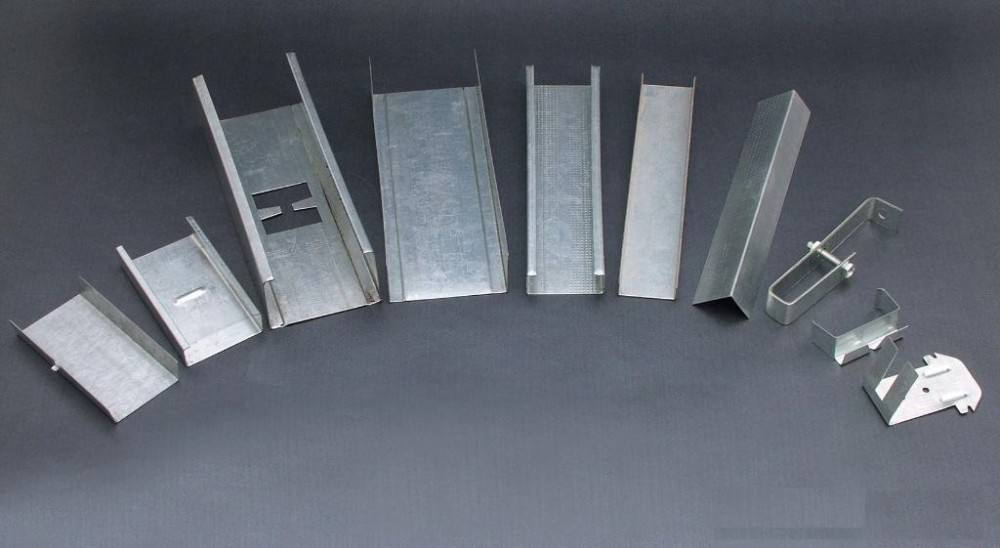

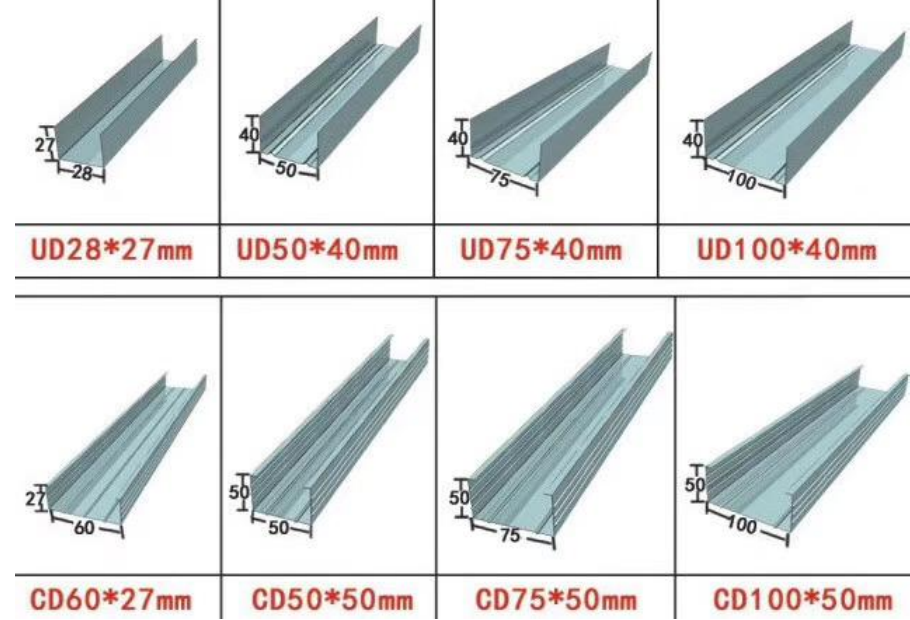

This Metal Profile CD UD UW CW Roll Forming Machine Drywall steel frame construction machine,is for making the stud and tracks for house frame.Usually have the CU,CW for the wall frame building,and CD/UD for the ceil building.

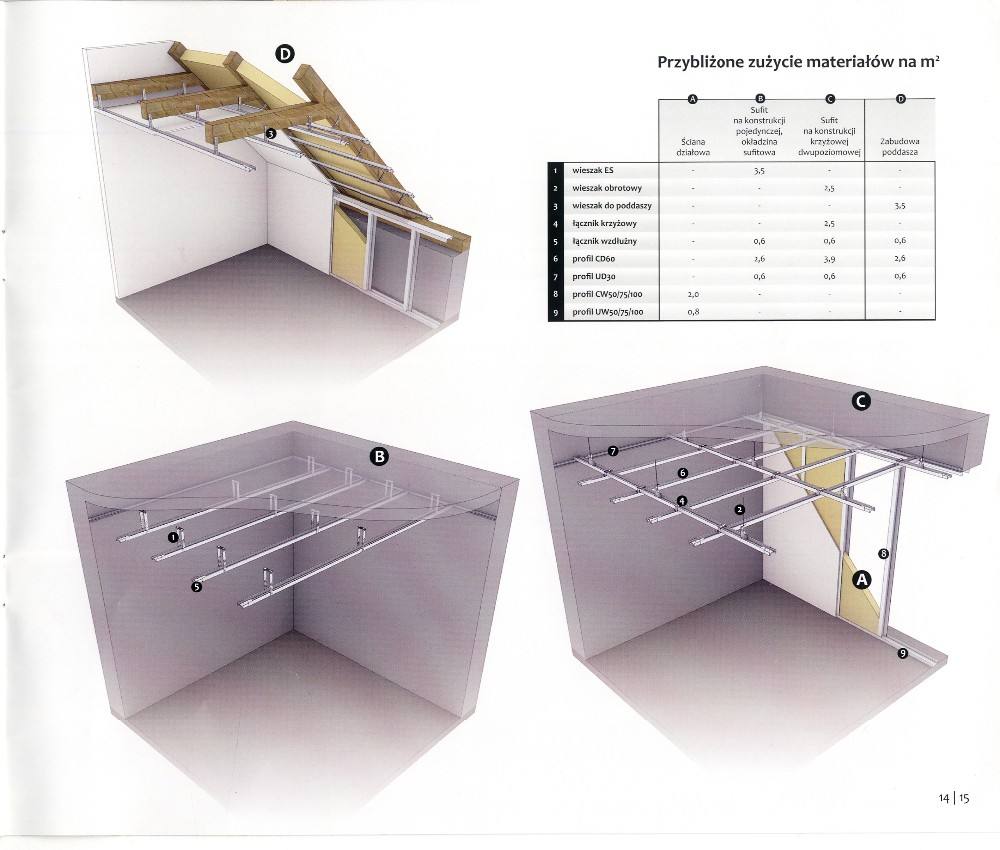

Here the usage of finished products for your reference.

The CU/Cw for the wall frame

The CD/UD for ceiling system

Our machine supports material thickness from 0.3-1.5 mm Double Furring And C Channel Machine with the full engineering technicaldata/specification. Designed and pre-engineered by experienced truss specialists using only the very latest software. Normally our machine could make truss for Indian, Australia, Egypet and other countries. The shapes of the trusss are like furring hat shape, U shape, C shape, L shape and others.

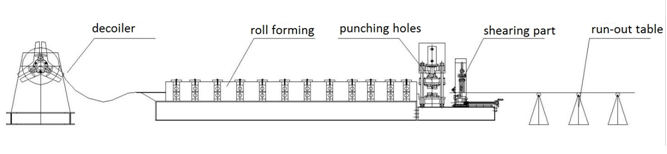

Working flow of Metal Profile CD UD UW CW Roll Forming Machine Drywall steel frame construction machine:

uncoiling-feeding-roll forming-punching-cutting-receiving table

1. Components of line of metal profile cd ud machine:

|

No.

|

Name

|

Unit

|

Qty

|

|

1

|

Decoiler

|

set

|

1

|

|

2

|

Entry Beach

|

set

|

1

|

|

3

|

Main Machine for roll forming

|

set

|

1

|

|

4

|

Cutting System

|

set

|

1

|

|

5

|

punching

|

set

|

1

|

|

6

|

Output Table

|

set

|

1

|

|

7

|

Control System(PLC)

|

set

|

1

|

|

8

|

hydraulic station

|

set

|

1

|

Main parameters of the machine:

|

Manual Decoiler

|

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system.

1. Loading capacity: 3T

2. Uncoiling width: 300mm

3. Inner diameter: 450-550mm

|

|

Roll forming machine

|

1. Size: 5300*1200*1400mm

2. Weight t: 4.2 tons

3. Voltage:380V/50HZ3Phase(as customer’s request)

4. Roller fixer : Guide column

5. Frame : middle plate welded Memorial arch frame type

6. Frame thickness:25mm

7. Drive mode: gear

8. Material of rollers: GCr12MoV

9. Material of shafts: 45# steel

10. Diameter of shafts: φ50mm

11. Number of rollers :12 rollers

12. Main power: 7.5kw

13. Speed: 0-40m/min

(Cycloidal planetary gear speed reducer)

|

|

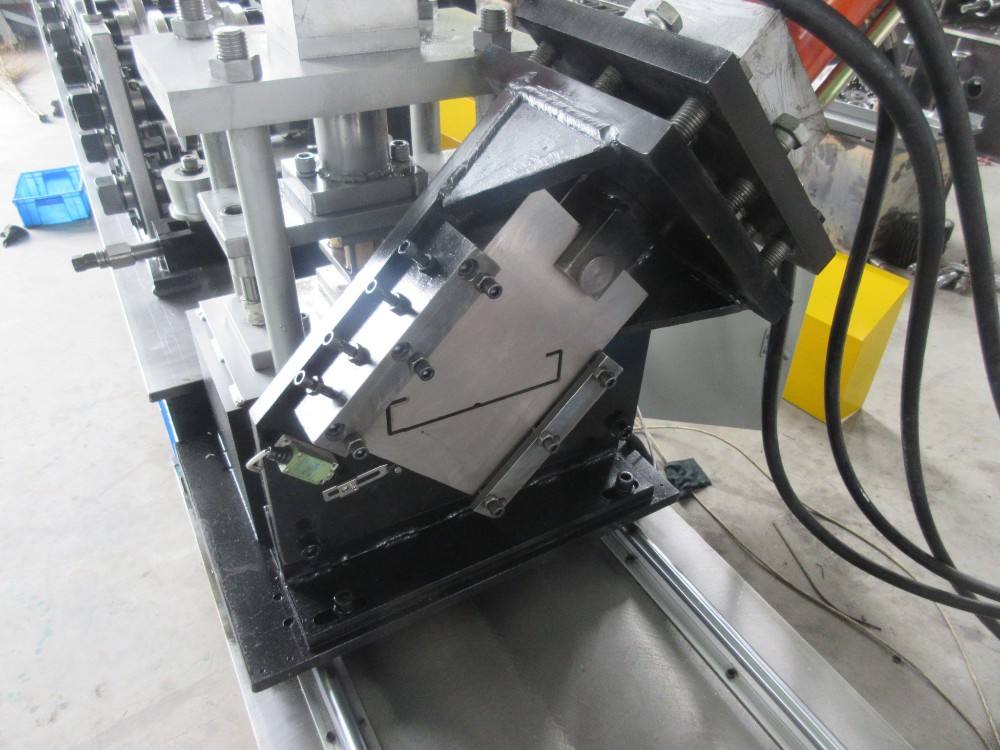

Cutting and punching

|

1. Mould material: Gcr12

2. Power supper: Hydraulic Station

3. Material of blades: Gcr12 quenched

4. Power supply : hydraulic power

5. Stroke switch : non-contact photoelectric switch

6. Servo motor: 4kw

The blade will automatic adjust the

position as the speed of the roll

forming machine.

Keep in the line with the running

speed of the roll forming machine.

when reach a set length, keep the

running speed constant, and cutting

the material.

|

|

Control Box

|

Feature:

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision

and lifetime.

2.Other electric element are Delta

3. Equipped with movable switch, air break, radiator,transformer & electric leakage protector for

operation convenience and safety

|

Some we have sold machines pictures for your reference:

more photos of this Metal Profile CD UD UW CW Roll Forming Machine Drywall steel frame construction machine